Uncategorized

Benefits of Fluted Polypropylene Sheet and Corrugated Plastic Container

If you are thinking of entering the product packaging business, let’s move on to the packaging materials. It is important to choose the most suitable from the options, Including cardboard, plastic, foil, film, metal, plastic, etc. This article will help you gain in-depth knowledge of plastic materials. It can be difficult for beginners to choose the right plastic material. However, businesses prefer Fluted Polypropylene Sheet for a number of reasons.

Understand the application of fluted polypropylene sheet:

This plastic packaging material is used in industries including food packaging, advertising, chemicals, signage and the semiconductor industry. It is widely used for many benefits, including high abrasion resistance, multi-layer, low cost, low maintenance, strong, durable, lightweight, flexible, endless design, etc. The biggest advantage of using

fluted polypropylene sheet is able to be used heavily outdoors and shipped over long distances without worrying about spoilage. So that your product is firmly protected, you can choose the fluted polypropylene sheet.

Benefits of corrugated plastic containers:

Maximum durability: One of the most durable forms of corrugated plastic is renowned in the construction industry for its scratch-free quality.

Easy to clean: It is easy to clean and can be used with both indoor and outdoor products.

Waterproof and recyclable: Corrugated board manufacturers and suppliers promise waterproof and recyclable properties. This makes it one of the most efficient materials used in the packaging industry.

Lightweight: It is so light that it can be used to support a limb in the event of a fracture.

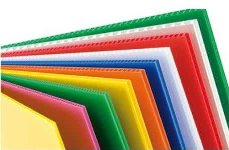

Colour and size options: Unlike other plastic products, corrugated plastic containers are available in various colours and thicknesses.

Ability to withstand different weather conditions: At normal temperatures, water, oil and other solvents, Most of them don’t have much impact, which makes them more effective during bad weather conditions.

Modifications can be made: Standard corrugated plastic can be modified with additives added to the sheet to meet various user requirements, such as flame retardants, custom colour corrosion, inhibitors, etc.